What Is an EHS Management System? Compliance,…

Explore how The Disrupt Labs computer vision AI-powered EHS…

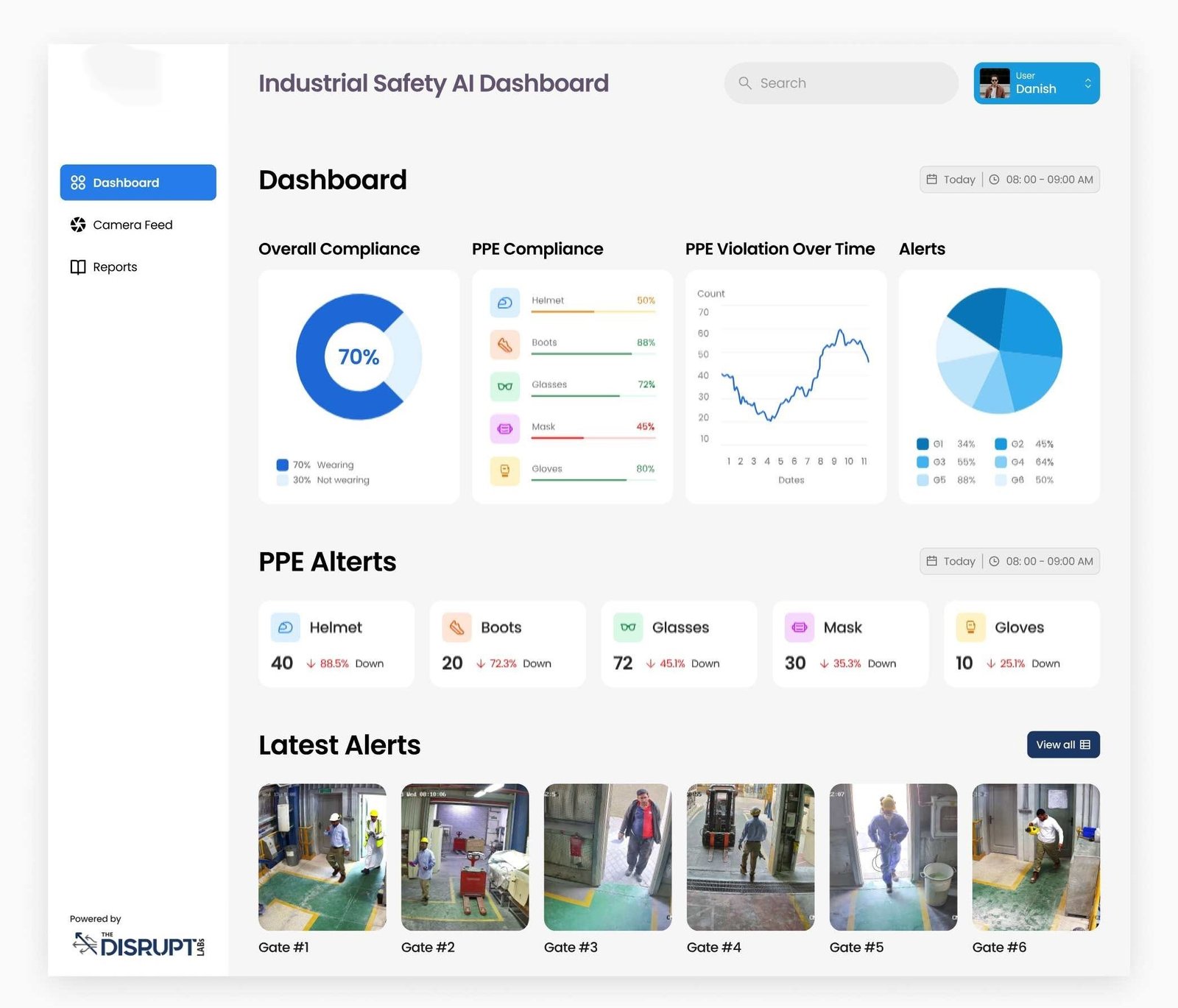

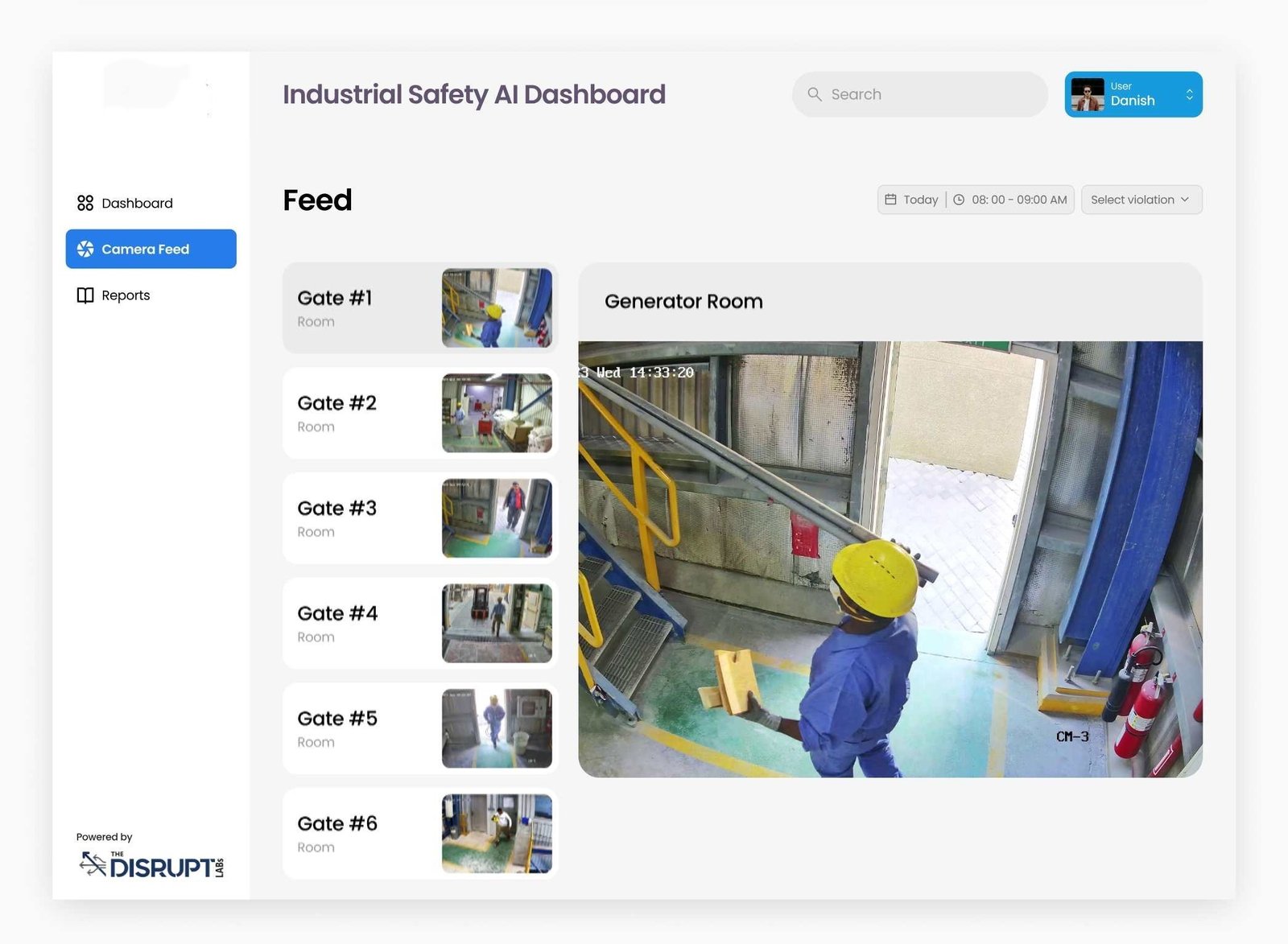

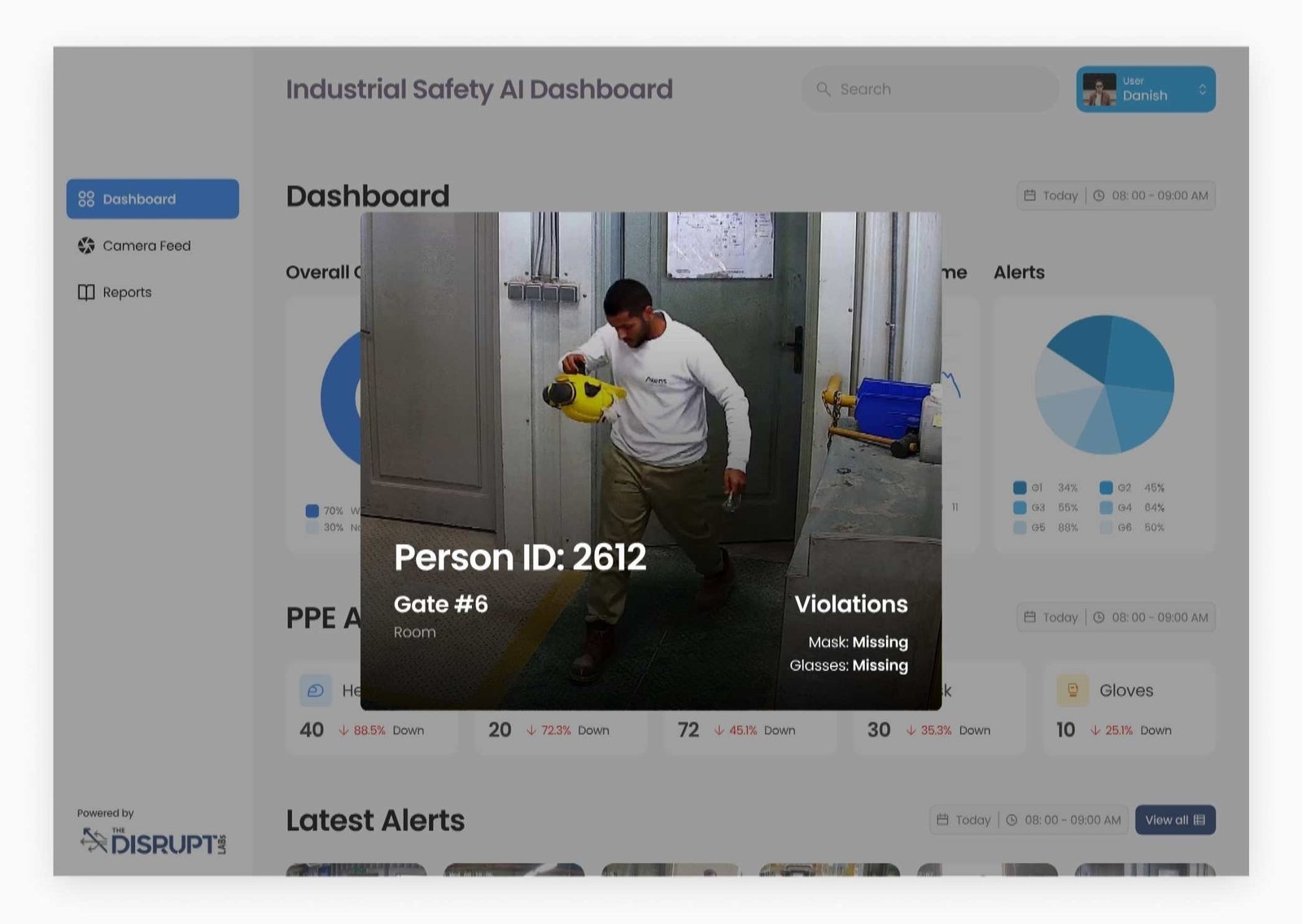

Upgrade Your Existing CCTV Infrastructure With Artificial Intelligence For Proactive Industrial Safety.

Upgrade Your Existing CCTV Infrastructure With Artificial Intelligence For Proactive Industrial Safety.

Focused Area

PPE is crucial for ensuring worker safety. Helmets, vests, boots, masks, and other gear are monitored to maintain a safe environment.

Clear pathways, unblocked emergency exits, and prompt spill cleanup are essential for preventing accidents.

AI monitoring ensures operator presence and restricted access, attention to suspended loads, machine proximity, and worker counts for safety.

Forklift safety is paramount. We ensure safe distances, proper parking, and adherence to designated aisles for efficient material handling.

Machine guards, closed electrical panels, stairrails, and camera integrity are monitored to enhance workplace safety.

During emergencies, we track person counts, respond to worker incidents, and ensure orderly evacuation using designated exits.

The Disrupt Labs provides AI computer vision for HSE management, ensuring 24/7 monitoring and proactive hazard detection. Our solution ensures safety compliance, efficient incident response, and data-driven decision-making. By reducing human error, we enhance safety and operational efficiency. Choose The Disrupt Labs for scalable AI solutions revolutionizing HSE management.

The Disrupt Labs, committed to better protect you around the world.

Where you will find the same quality of service and dedication around the world.

Making us one of the leading AI Safety Solution company around the globe.

Real-Time Industrial Safety Solutions

At The Disrupt Lab, we transform experiences by leveraging cutting-edge technology like Vision AI to enhance safety and prevent accidents. We use convolutional neural network and transformer to develop advance Computer Vision AI models for enhanced accuracy. Explore the capabilities of our advanced safety monitoring software.

Steps we follow

The Disrupt Labs Follows Three Simple Steps Engagement Process!

Goal: Review your current

CCTV network and discuss

potential Alerts

Deliverables: A detailed

Assessment report + POC +

Implementation Roadmap.

Outcome: You will have a

detailed plan for how AI Visual

Automation Enhance your

Security, Safety and

Compliance.

Format: 2-week engagement

Conducted virtually.

Goal: Source and Install the

relevant hardware needed and

optimize the AI models for the

specific real time alerts.

Deliverables: Real time AI Alerts

Software for defined Surveillance

tasks.

Outcome: Better security, safety

and compliance.

Format: Client Side PM engages in

Weekly calls to ensure smooth

implementation with our PM.

Goal: Ensure the software is updated and maintained.

Deliverables: Remote and onsite support for any issues.

Outcome: Make sure the software continues to provide value to the client.

Format: Monthly check-ins to discuss potential issues and realign on any compliance rules.

Steps we follow

The Disrupt Labs Follows Three Simple Steps Engagement Process!

Explore how The Disrupt Labs computer vision AI-powered EHS…

Discover how Personal Protective Equipment (PPE) protects workers from…

Explore how AI-powered EHS compliance management in 2025 uses…

Discover how our advanced safety AI solutions can transform your workplace and what you need to get started.