What are the Vision AI Solutions for…

AI solutions for workplace safety enable industries to proactively…

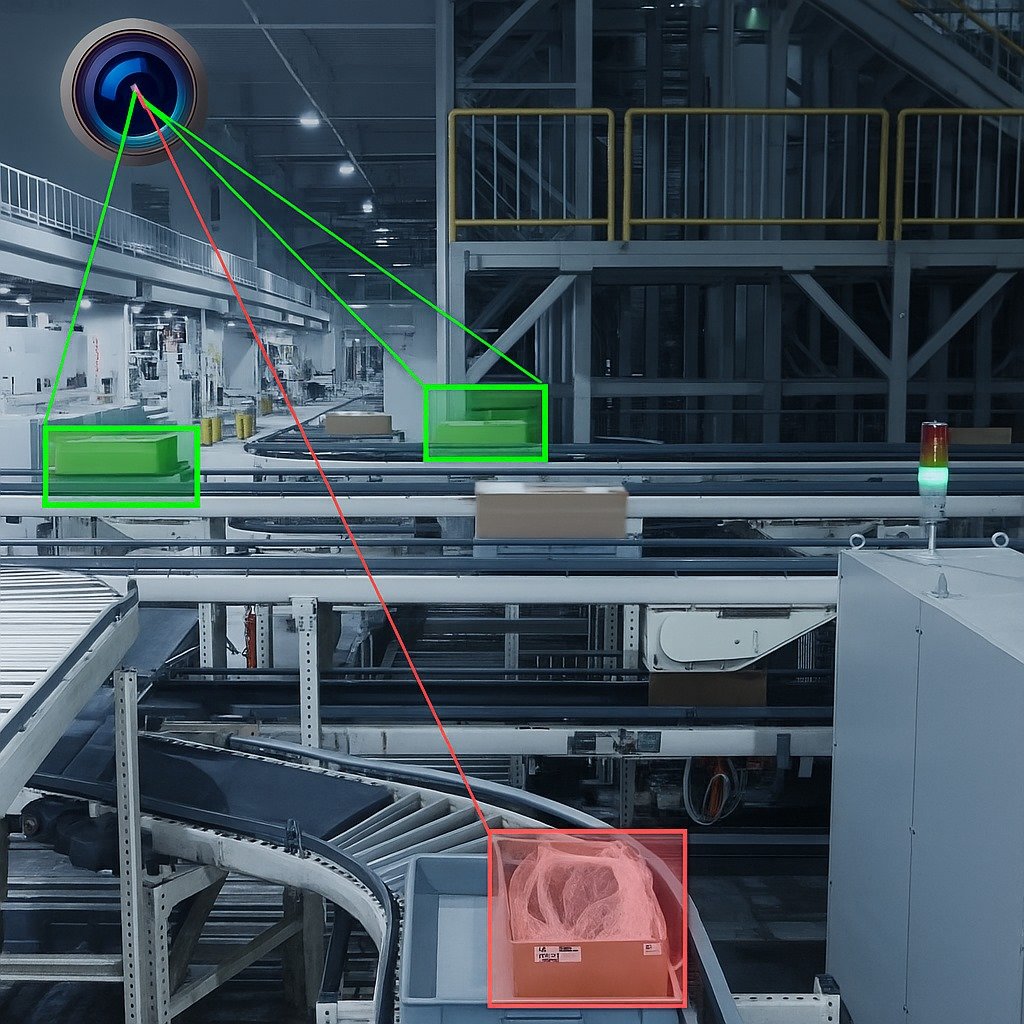

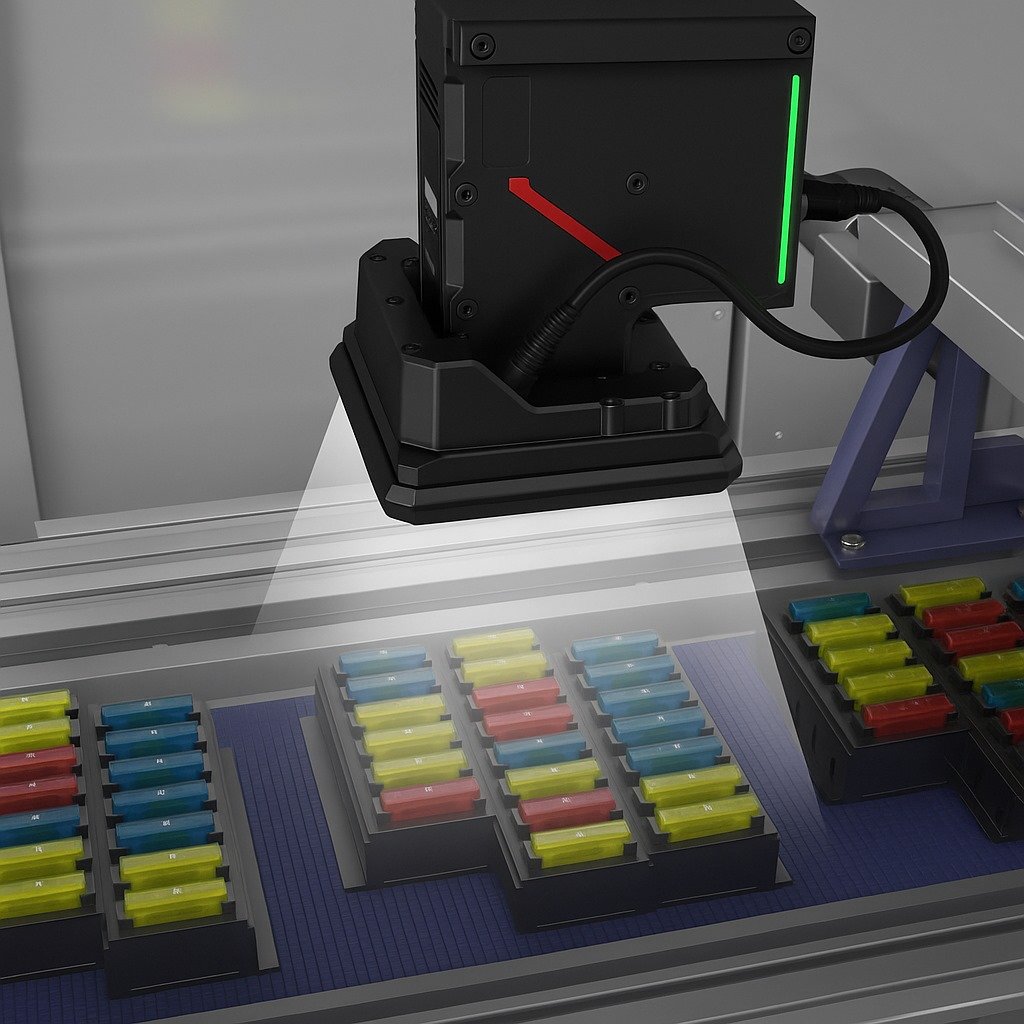

The Disrupt Labs enhances manufacturing precision by automating visual inspection through advanced computer vision. With Inspection AI, organizations gain instant insights into product quality detecting defects, validating dimensions, and verifying print accuracy to ensure every product meets the highest standards of excellence.

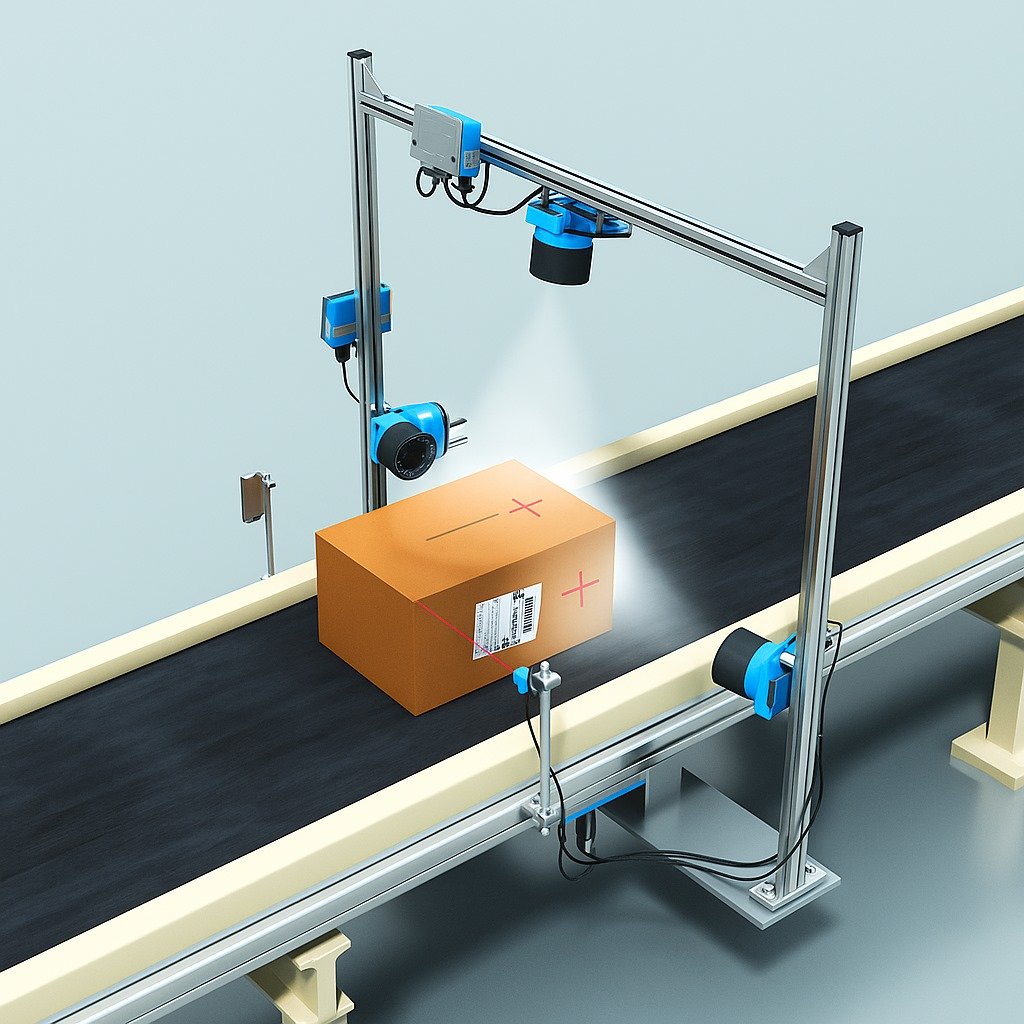

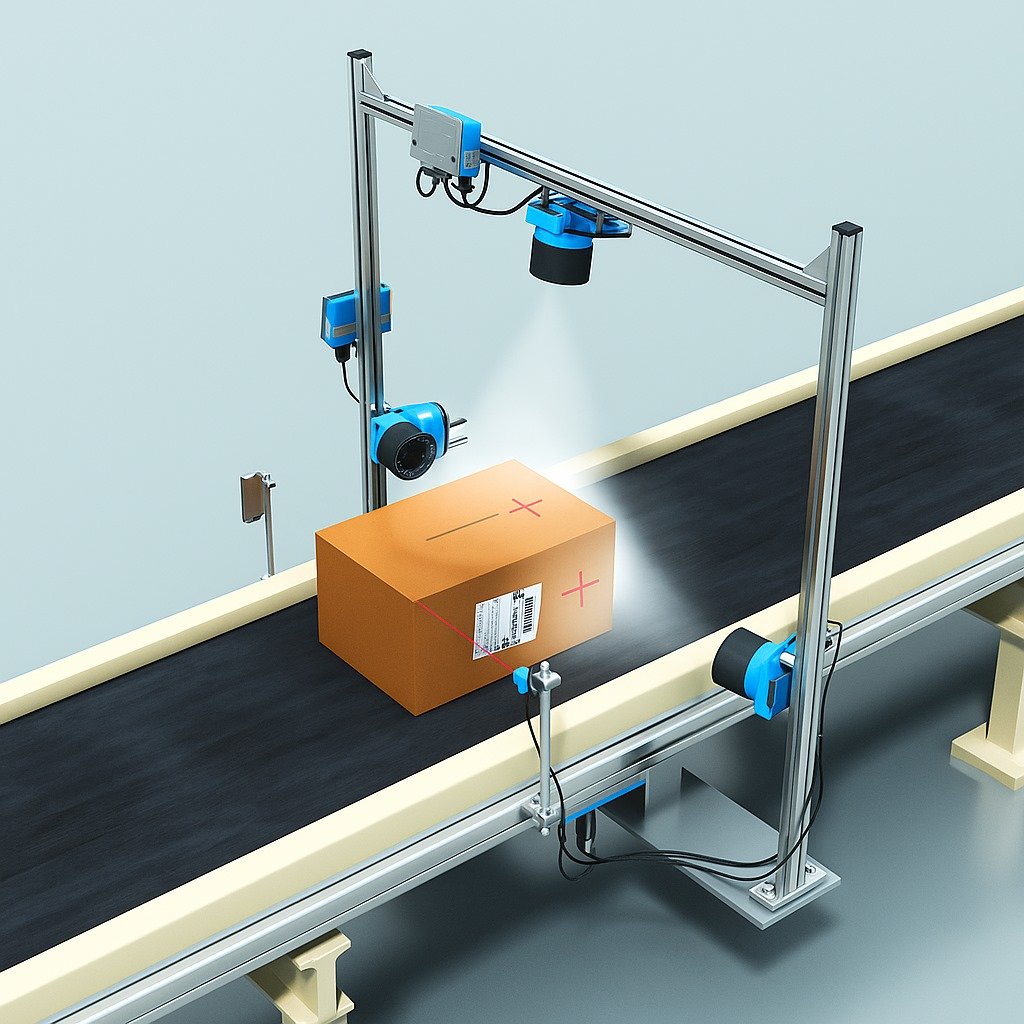

Automatically detects and verifies barcodes on products, pallets, and packaging through video streams. It eliminates manual scanning errors, improves traceability, and accelerates warehouse, manufacturing, and distribution operations with seamless integration into existing camera systems.

Performs real-time measurement and high-speed counting of products.. It detects inconsistencies in size, shape, or quantity preventing quality and packaging errors while maintaining precise inventory control and production accuracy.

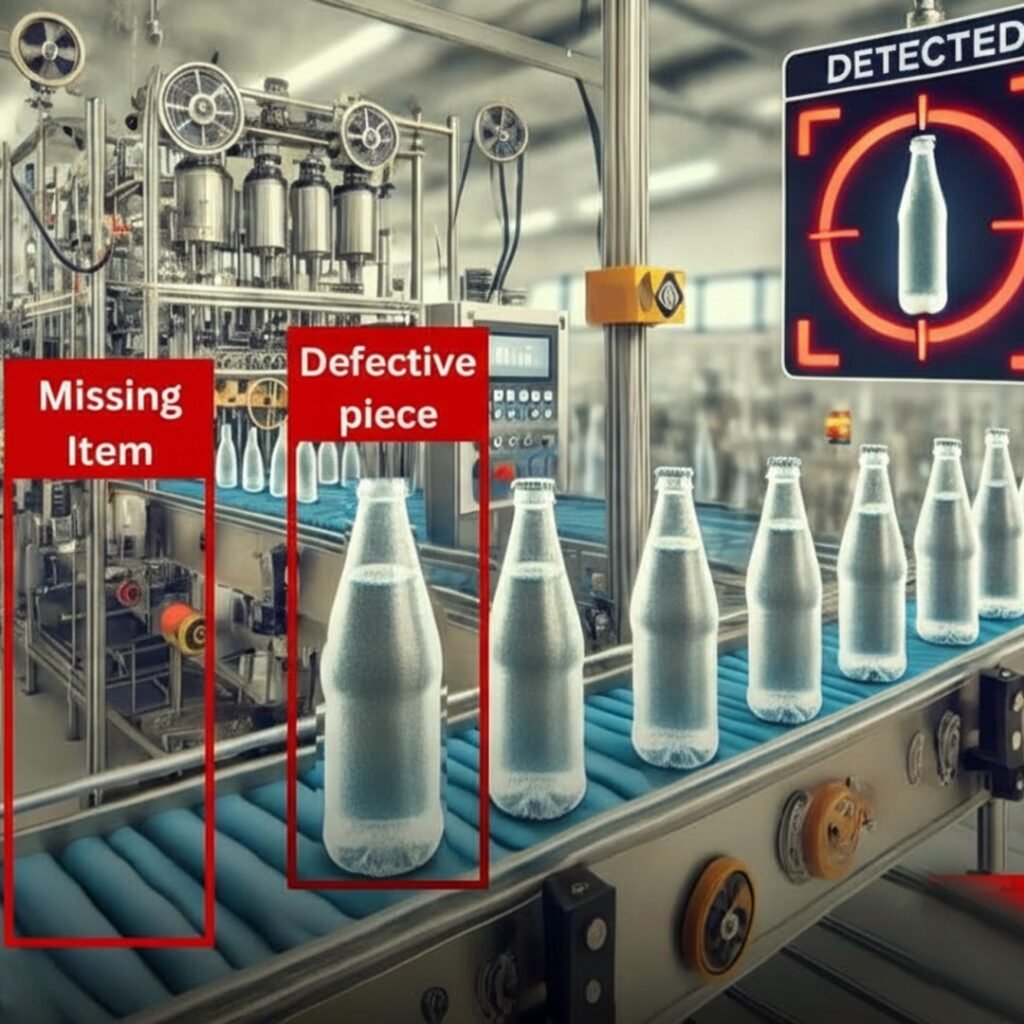

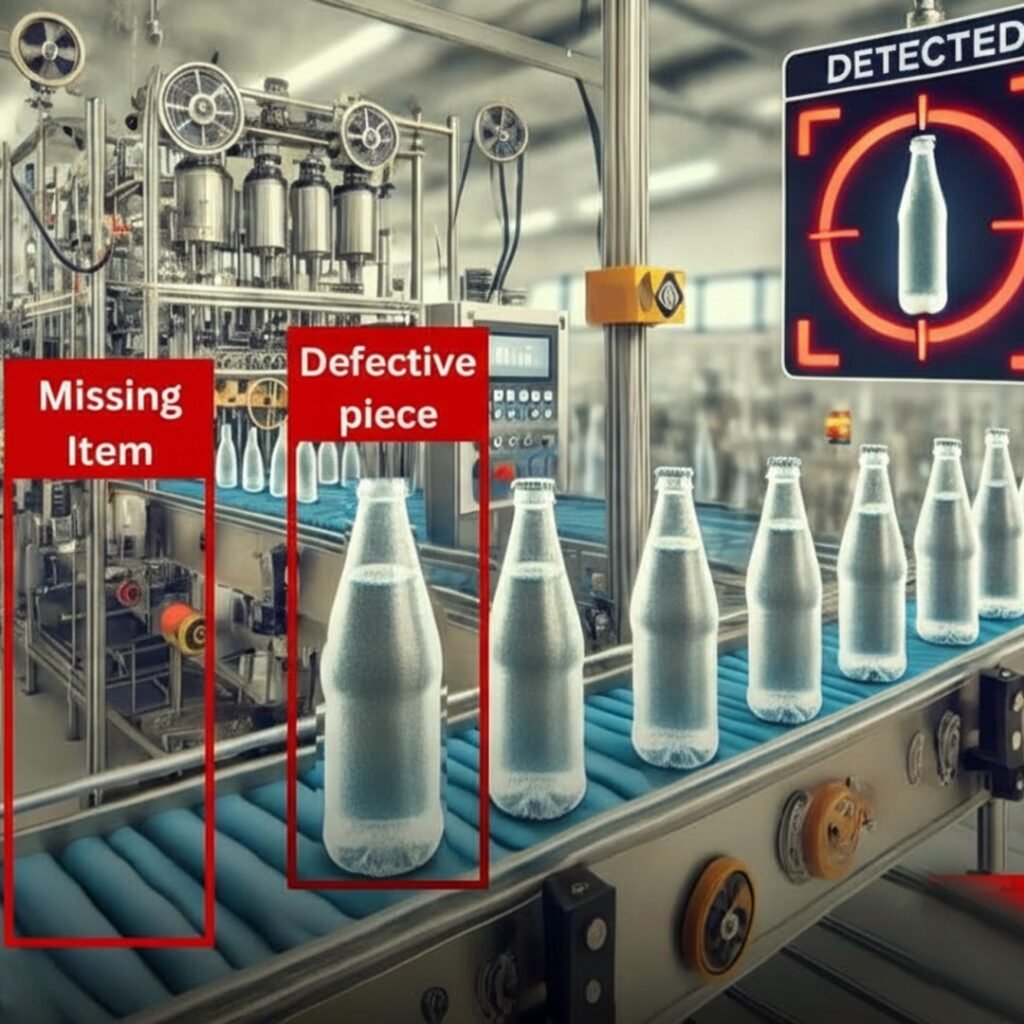

Identifies surface defects, cracks, scratches, dents, or missing components using high-resolution video analysis. The AI system ensures consistent inspection accuracy, reducing manual rework and improving production yield.

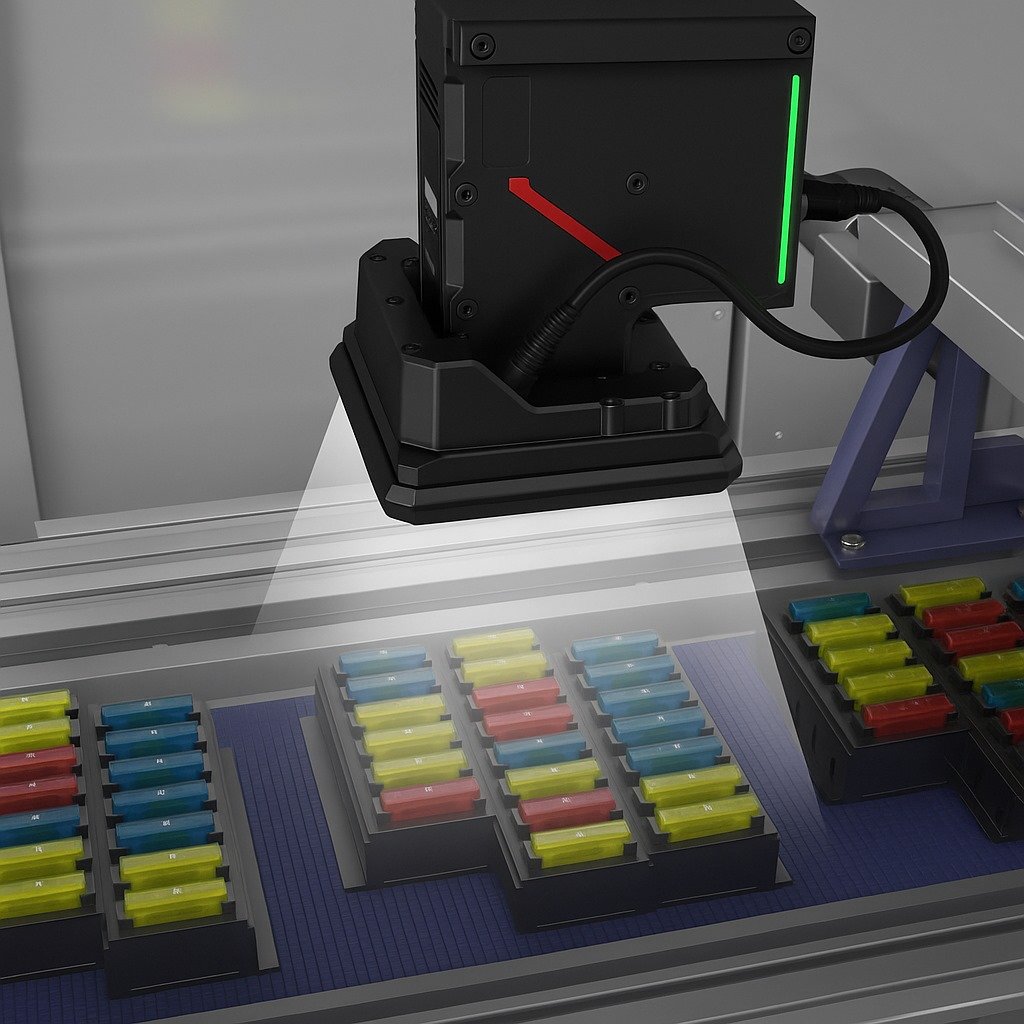

Monitors product color consistency across batches to ensure visual and brand quality. It automatically detects shade variations or printing errors that could impact customer satisfaction or compliance standards.

Compares live visuals with reference templates to validate product design accuracy. This ensures correct labeling, orientation, and component placement throughout the production process.

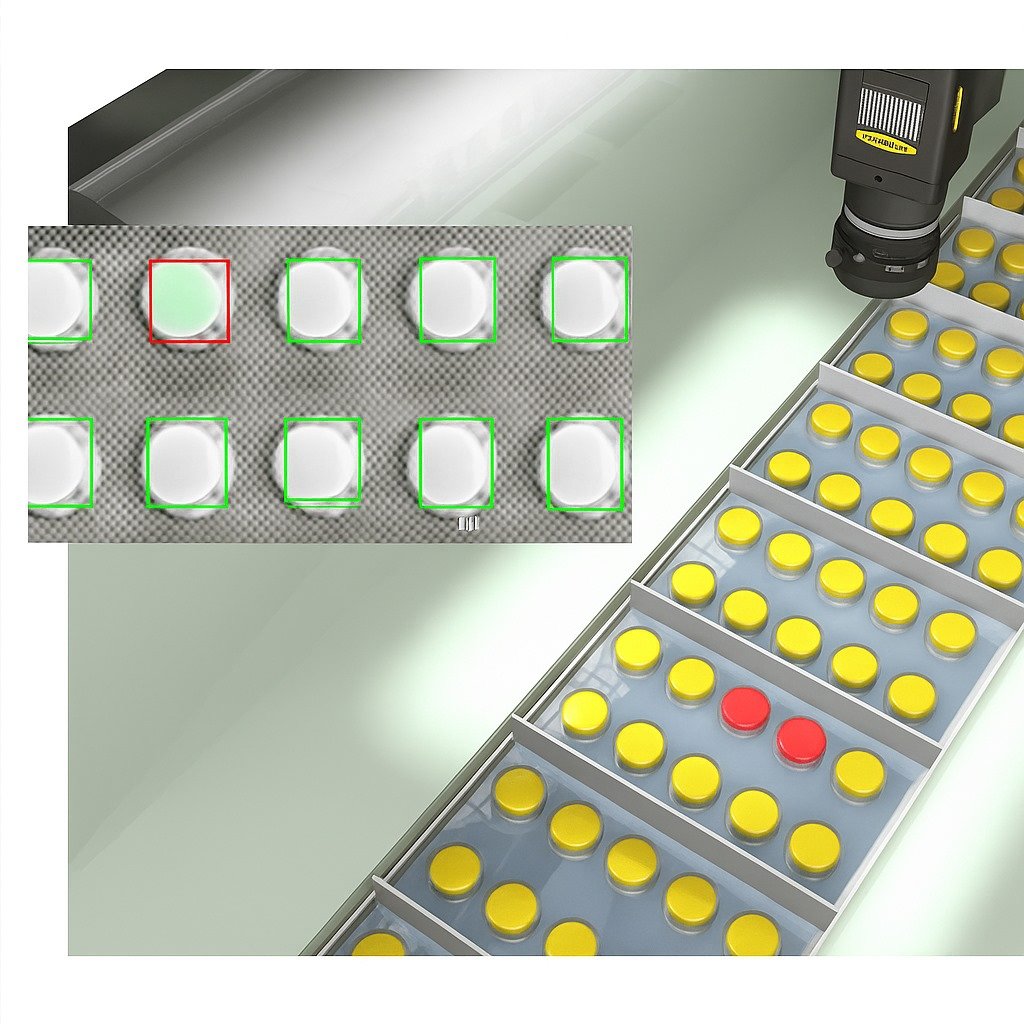

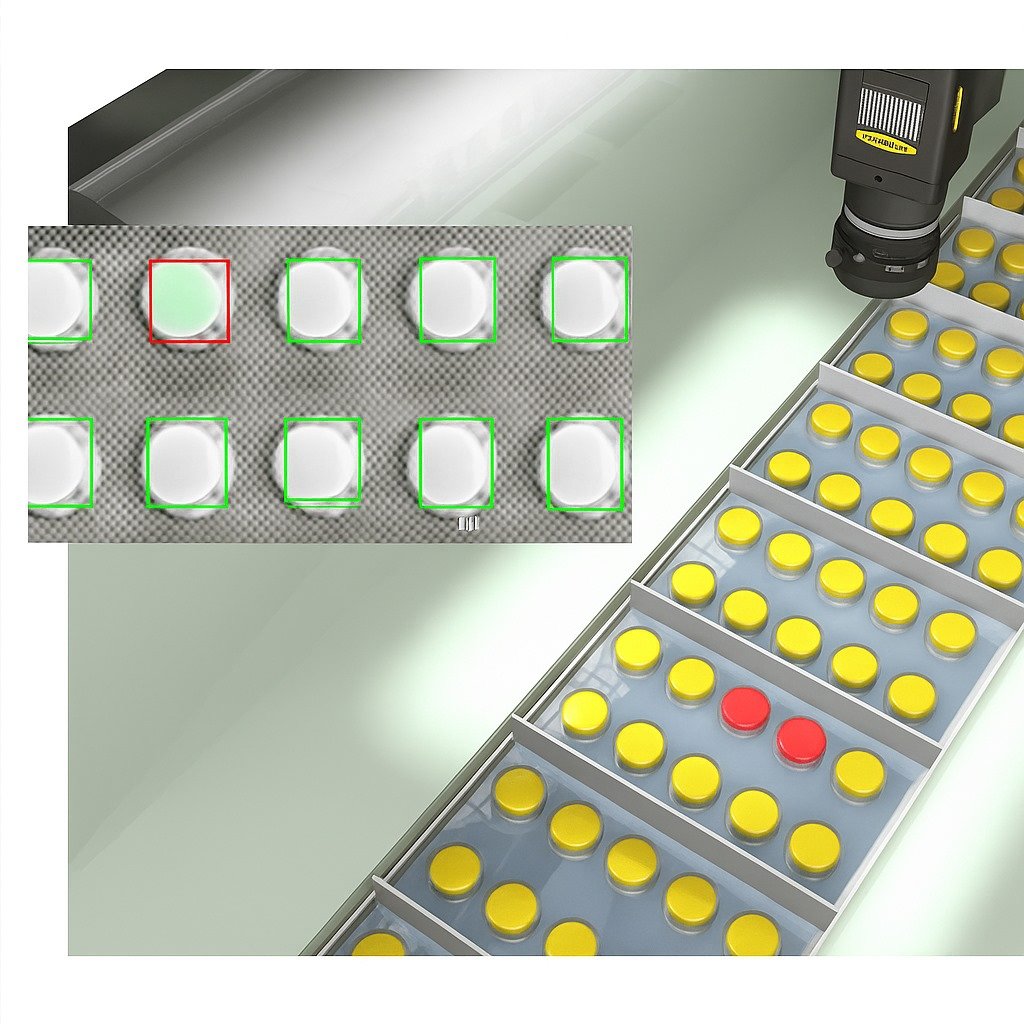

Inspects blister packs for missing tablets, sealing defects, or misaligned cavities.. It ensures pharmaceutical and consumer goods packaging meets strict quality standards before dispatch.

Detects misaligned or skewed prints on labels, cartons, or packaging. The system enhances print precision and reduces waste caused by misprints or misfeeds in high-speed production lines.

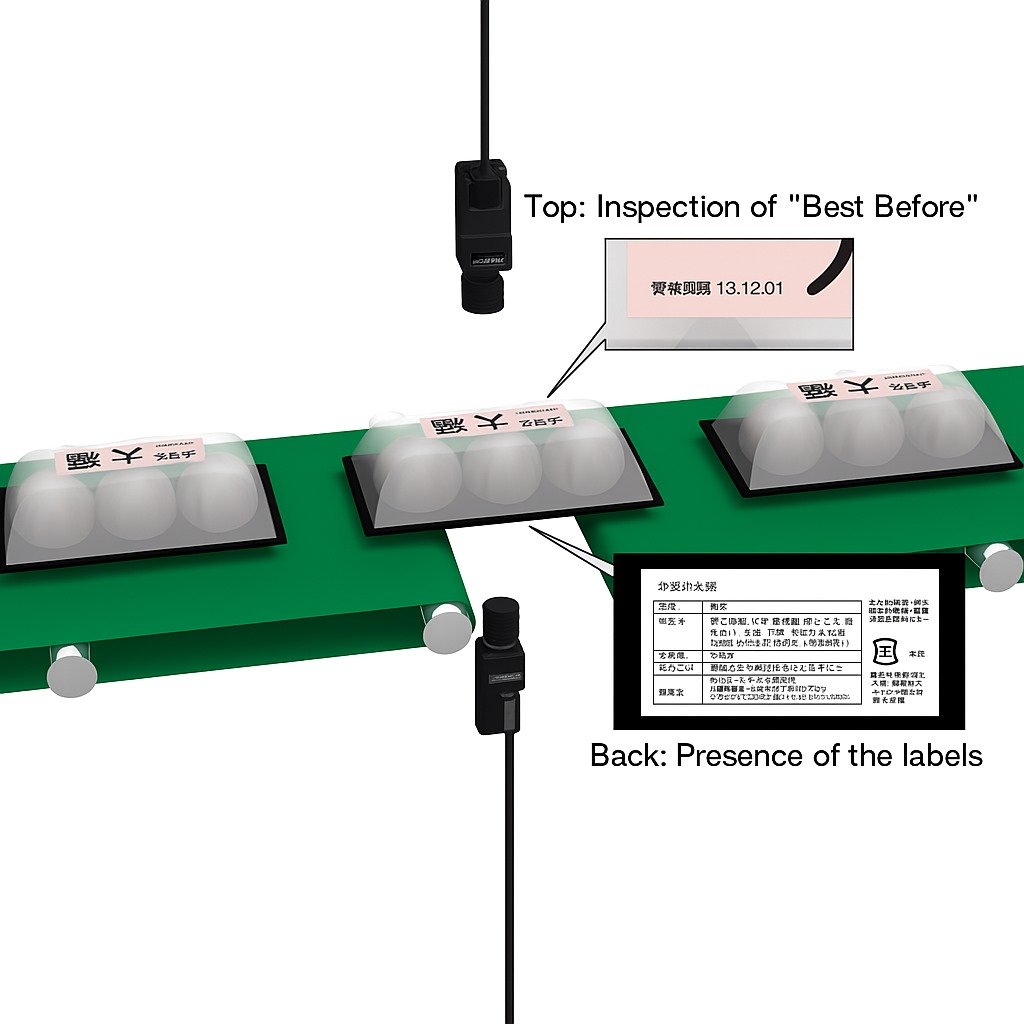

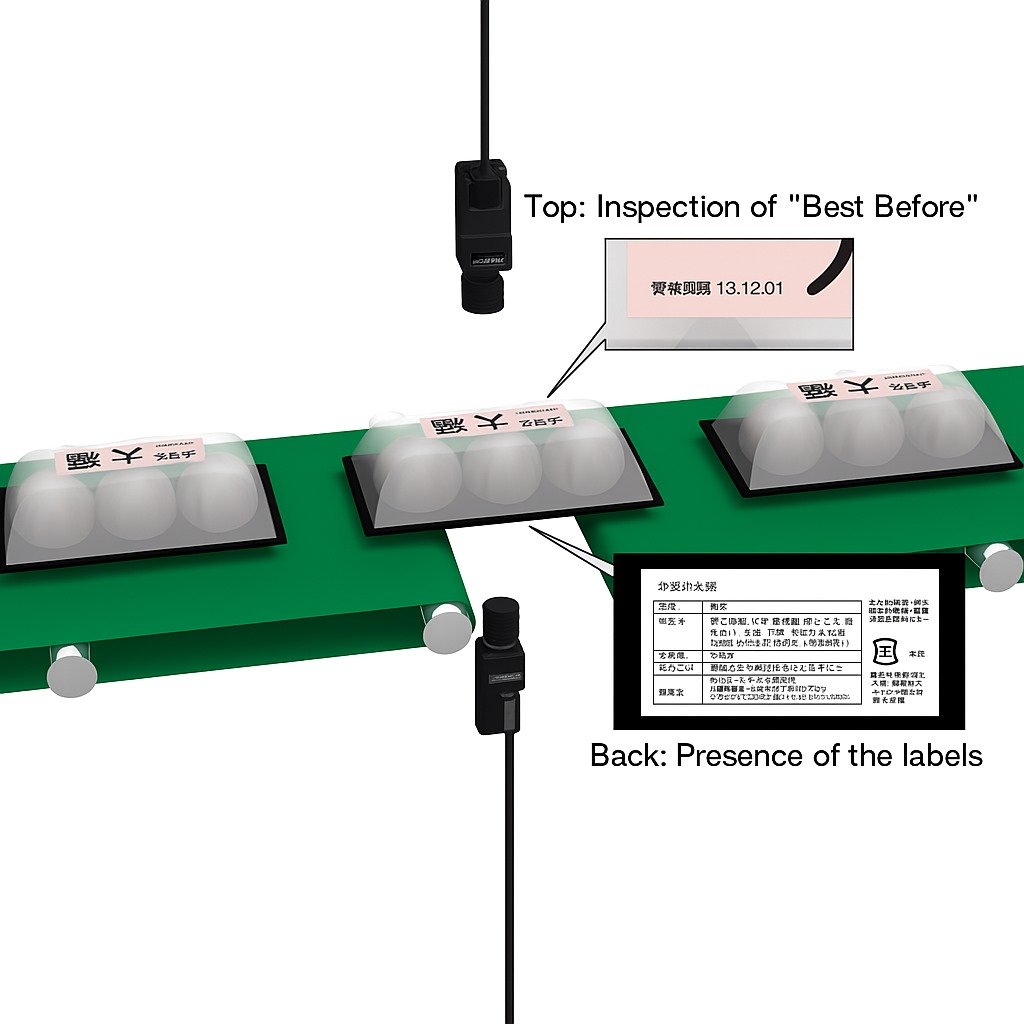

Uses Optical Character Recognition (OCR) to validate printed text, tag, labels, batch codes, or expiry dates. It ensures data accuracy, compliance with labeling standards, and traceability throughout the supply chain.

Analyzes bottle or container caps for presence, sealing quality, and alignment. The AI detects cross-threading, looseness, or missing caps to prevent leakage, contamination, or packaging rejections.

Automatically detects and verifies barcodes on products, pallets, and packaging through video streams. It eliminates manual scanning errors, improves traceability, and accelerates warehouse, manufacturing, and distribution operations with seamless integration into existing camera systems.

Performs real-time measurement and high-speed counting of products.. It detects inconsistencies in size, shape, or quantity preventing quality and packaging errors while maintaining precise inventory control and production accuracy.

Identifies surface defects, cracks, scratches, dents, or missing components using high-resolution video analysis. The AI system ensures consistent inspection accuracy, reducing manual rework and improving production yield.

Monitors product color consistency across batches to ensure visual and brand quality. It automatically detects shade variations or printing errors that could impact customer satisfaction or compliance standards.

Compares live visuals with reference templates to validate product design accuracy. This ensures correct labeling, orientation, and component placement throughout the production process.

Inspects blister packs for missing tablets, sealing defects, or misaligned cavities.. It ensures pharmaceutical and consumer goods packaging meets strict quality standards before dispatch.

Detects misaligned or skewed prints on labels, cartons, or packaging. The system enhances print precision and reduces waste caused by misprints or misfeeds in high-speed production lines.

Uses Optical Character Recognition (OCR) to validate printed text, tag, labels, batch codes, or expiry dates. It ensures data accuracy, compliance with labeling standards, and traceability throughout the supply chain.

Analyzes bottle or container caps for presence, sealing quality, and alignment. The AI detects cross-threading, looseness, or missing caps to prevent leakage, contamination, or packaging rejections.

See how The Disrupt Labs is redefining workplace safety with AI

Founded in January 2021, The Disrupt Labs (TDL) is a pioneering Safety Technology Company. Led by a Ph.D. in AI and supported by a team of passionate AI developers, TDL is backed by experienced HSE professionals and Silicon Valley angel investors.

Our mission is rooted in the conviction that every worker deserves to feel safe and secure at work. We are dedicated to enhancing workplace safety through innovative solutions in PPE monitoring, housekeeping practices, area controls, and ergonomic assessments.

Partner with us to transform your workplace into a safer and more secure environment for everyone.

AI solutions for workplace safety enable industries to proactively…

A GMP compliance audit ensures pharma quality, safety and…

Learn how real-time CCTV analytics and AI are transforming…

Discover how our advanced safety AI solutions can transform your workplace and what you need to get started.

Got something on your mind? Share the details with us and we’ll be in touch soon