AI Visual Inspection: What It Is, How It Works, and Its Role in Modern Manufacturing

Introduction to AI Visual Inspection

Struggling with time-consuming, manual inspection processes in your manufacturing operations? These labor-intensive checks are prone to human error, risking product quality and efficiency. Discover how AI-powered visual inspection and quality assurance automation can transform industrial manufacturing.

Visual inspection plays a critical role in manufacturing quality control, ensuring products meet defined standards before reaching customers. It is used to detect fabric defects, verify packaging integrity, and confirm label accuracy supporting safety, regulatory compliance, and customer trust. However, traditional inspection methods, whether manual or rule-based, struggle to keep pace with today’s high-speed, high-variation production environments.

Even a single undetected defect can result in recalls,compliance violations, or reputational damage. Industries such as pharmaceuticals, textiles, and packaging rely heavily on accurate visual checks to ensure consistency and traceability. As manufacturing operations expand, the need for faster, smarter, and more reliable inspection solutions becomes essential.

What Is AI-Powered Visual Inspection?

AI-powered visual inspection is an advanced approach to quality and process monitoring that uses computer vision AI to automatically analyze visual data from industrial cameras. Instead of relying on manual checks or fixed rule-based systems, it continuously examines products, materials, and production activities to identify defects, inconsistencies, and process deviations as they occur. This enables manufacturers to maintain consistent quality standards while reducing dependency on human inspection.

For industrial operations, AI-powered visual inspection provides scalable and reliable inspection capabilities across complex and high-speed environments. By learning from real production data, the system adapts to product variations, changing conditions, and evolving quality requirements. This allows organizations to improve inspection accuracy, detect issues earlier, and gain actionable insights that support better decision-making, operational efficiency, and long-term quality improvement

How AI Visual Inspection Works

AI Visual inspection solutions follow a structured, production-ready workflow designed to deliver accurate, real-time insights without disrupting manufacturing operations.

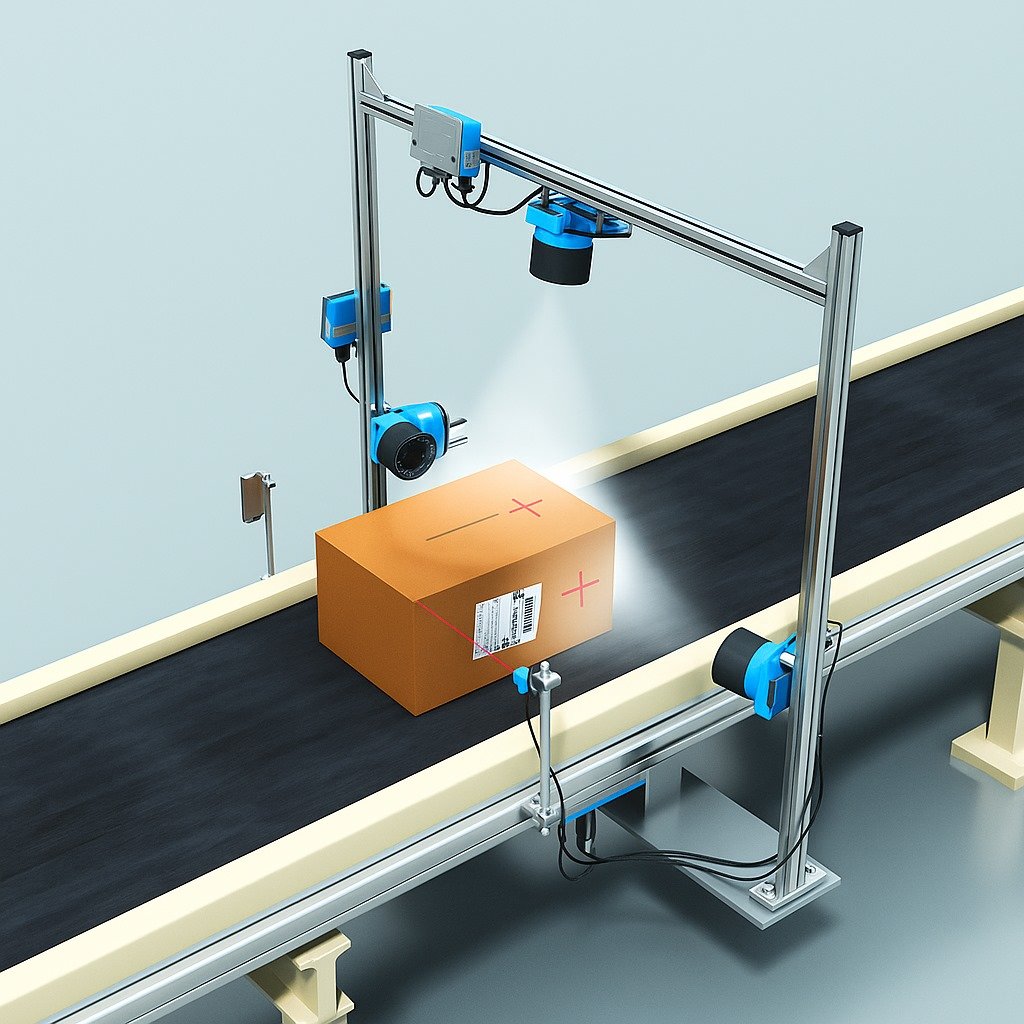

Image Capture and Industrial Sensors

High-resolution industrial cameras and sensors are strategically deployed across production lines. These capture continuous visual data from conveyors, and packaging lines. Controlled lighting and optimized camera placement ensure image consistency even in challenging factory environments.

Deep Learning–Driven AI Solutions

Captured visual data is used to train deep learning-driven AI solutions that learn to differentiate between acceptable products and defective ones. By analyzing textures, shapes, edges, and anomalies, these solutions develop a deep understanding of product quality standards.

Real-Time Defect Detection

Once deployed, it performs real-time defect detection by analyzing live video streams. Scratches, cracks, missing components, incorrect labels, seal failures, and contamination can be identified within milliseconds without interrupting production flow.

Automated Decision-Making

Based on inspection results, AI enabled quality solutions trigger automated actions such as rejecting defective items, alerting quality teams, or flagging process deviations. This enables real-time defect detection and industrial efficiency solutions that reduce waste, rework, and unplanned downtime.

At The Disrupt Labs, our AI visual inspection solutions integrate seamlessly with existing manufacturing infrastructure, supporting fast deployment and measurable improvements in operational performance.

Benefits of AI Visual Inspection in Manufacturing

Implementing an inspection solution delivers measurable business and operational benefits across manufacturing operations.

Higher Accuracy and Consistency

AI-powered inspection solutions evaluate every unit with consistent precision, removing variability caused by human fatigue or subjective judgment. This ensures uniform quality standards across shifts, production lines, and facilities, delivering reliable inspection results.

Faster Production with Fewer Bottlenecks

AI visual inspection solutions work in real time alongside production lines, removing the need for manual inspection pauses. This helps keep production running smoothly, reduces delays, and allows manufacturers to achieve higher output without compromising quality.

Reduced Human Error

By automating repetitive visual inspection tasks, manufacturers reduce dependency on manual checks and significantly lower the risk of missed defects.

Real-Time Quality Assurance

Defects are identified instantly, allowing manufacturers to address root causes before issues escalate. This proactive approach minimizes scrap, rework, and costly recalls.

Compliance, Productivity, and Operational Accuracy

AI-based visual inspection solutions support regulatory compliance, improve audit readiness, and enhance operational accuracy by automatically detecting defects and process deviations.

By enabling continuous, computer vision AI based monitoring, these solutions also improve workforce productivity and support proactive safety through PPE compliance, helping reduce quality risks and workplace incidents in manufacturing environments.

Industrial Use Cases

Pharmaceuticals

In pharmaceutical manufacturing, quality and safety are non-negotiable. AI visual inspection ensures packaging integrity, verifies label accuracy, checks batch codes and expiry dates, and detects contamination or missing components. These solutions help manufacturers meet strict regulatory requirements while maintaining production efficiency.

Textiles

Textile manufacturers use AI-driven inspection analytics to identify weaving defects, color inconsistencies, fabric defects, and pattern misalignments in real time. This improves finished product quality and reduces material waste.

Packaging & Labeling

AI-driven inspection verifies barcodes, seals, caps, and traceability information during high-speed packaging operations. This ensures accurate labeling, reduces shipping errors, and supports end-to-end supply chain transparency.

AI Visual Inspection vs Manual Visual Inspection

| Aspect | AI Visual Inspection | Manual Visual Inspection |

| Inspection Speed | Operates in real time at full production speed | Slower and dependent on human pace |

| Accuracy & Consistency | High accuracy with consistent results across all shifts | Varies due to fatigue, attention, and experience |

| Defect Detection | Detects subtle and complex defects using learned patterns | Often misses small or inconsistent defects |

| Operational Downtime | Runs continuously without interrupting production | May require pauses or rechecks |

| Cost Efficiency | Lower long-term costs through automation | Higher ongoing labor and rework costs |

| Reporting & Traceability | Automatic logging with visual evidence and reports on Dashboard | Limited documentation and manual records |

| 24/7 Operation | Supports continuous, round-the-clock inspection | Limited by shift schedules |

While manual inspection may still have limited use in specific scenarios, AI-powered visual inspection delivers significantly higher efficiency, accuracy, and scalability for modern manufacturing environments. At The Disrupt Labs, we provide AI-driven visual inspection and industrial quality solutions that help manufacturers move beyond reactive quality control toward proactive, data-driven decision-making and continuous improvement.

Challenges and Limitations

AI Visual inspection offers significant advantages, its success depends on thoughtful implementation and close alignment with manufacturing workflows. These solutions require high-quality, well-labeled data to achieve optimal accuracy, making data preparation a critical early step. In addition, real-world factory conditions such as dust, vibration, variable lighting, and camera positioning can influence performance if not properly addressed.

However, these challenges are not barriers but design considerations. With the right solution architecture, calibration manufacturers can effectively manage these limitations and deploy visual inspection solutions that are robust, reliable, and production-ready.

Future of AI in Manufacturing Visual Inspection

The future of AI visual inspection in manufacturing is centered on greater automation, accuracy, and reliability across production processes. As AI models continue to improve, visual inspection systems will become more capable of detecting defects in real time while operating seamlessly at production speed. This allows manufacturers to maintain consistent quality with reduced manual inspection effort.

AI powered visual inspection solutions enable manufacturers to move from reactive quality control to predictive quality management. This helps identify potential issues earlier, reduce defects and waste, minimize production disruptions, and support continuous quality improvement across manufacturing operations.

Conclusion

Computer vision–based visual inspection has become critical for modern manufacturing, enabling organizations to maintain consistent quality standards while scaling operations efficiently. By providing real-time defect detection, higher inspection accuracy, and reliable quality monitoring, AI-powered visual inspection helps manufacturers reduce errors, improve compliance, and streamline production processes.

At The Disrupt Labs, we deliver practical computer vision AI inspection solutions designed for real-world manufacturing environments. Contact us today to learn how AI-powered visual inspection can enhance quality control, improve operational efficiency, and support long-term manufacturing excellence.

Frequently Asked Questions

It detects defects instantly, reduces rework and downtime, and allows production lines to maintain consistent, high-speed operations.

It significantly reduces dependence on manual inspection while delivering faster, more consistent, and scalable quality results.

Visual inspection solutions can detect fabric defects, incorrect labels, seal issues, contamination, color variations, and dimensional inconsistencies.

Yes, it inspects products instantly on production lines without slowing operations.

It ensures products meet regulatory and quality standards by detecting defects early.